Concrete Mike LLC's epoxy flooring solutions in Satellite Beach deliver flooring systems that protect against salt, moisture, and daily use—excellent for coastal settings. Pick from custom color, textured, high-gloss, or sleek finishes to align with your safety needs and aesthetic goals. Rely on thorough preparation, meticulous installation, and assistance with every design choice. Care is easy, and durability is unmatched. Begin now to discover just how transformative our epoxy solutions can be for your space.

Critical Findings

The Benefits of Epoxy Floor Solutions for Satellite Beach Homes

When you opt for epoxy flooring for your Satellite Beach property, you're investing in a surface that's engineered to endure the region's unique coastal challenges. Epoxy's continuous, non-porous finish guards against moisture and salt intrusion, avoiding damage typical in coastal environments. You'll discover it's easy to clean and won't support mold or bacteria, promoting a healthier indoor environment and reducing your overall environmental impact. Regarding cost comparison, epoxy flooring offers an remarkable return on investment. Its durability decreases the need for frequent repairs or replacement, saving money over time compared to conventional flooring options. You also enjoy reduced maintenance costs, thanks to epoxy's resistance to stains, chemicals, and abrasion. It's a wise, eco-friendly flooring solution for any property.

Different Epoxy Flooring Finish Options

Although every space in Satellite Beach has unique requirements, epoxy flooring comes with a range of finishes created to address specific requirements. You can select from a wide array of color choices, allowing your flooring to match your building's aesthetic or make a bold statement. For better safety and functionality, texture varieties include polished, high-gloss surfaces plus slip-resistant finishes produced by including aggregates or quartz. Metallic epoxy delivers a dynamic, marbled finish, while flake systems offer both visual appeal and increased durability. For industrial or high-traffic areas, solid color and self-leveling epoxy offer continuous, simple to maintain finishes. By strategically selecting the right blend of color choices and texture varieties, you'll secure your epoxy flooring not only appears remarkable but also serves at its peak for your requirements.

The Installation Process: What You Need to Know

When starting your epoxy flooring project, it's essential to make sure the surface is adequately prepared to secure strong adhesion. Subsequently, exact application methods are used to spread the epoxy uniformly and avoid defects. Lastly, you'll need to allow the floor to set and give it a finish for maximum durability and a polished, professional appearance.

Steps for Surface Preparation

When initiating epoxy flooring work in Satellite Beach, meticulous surface preparation guarantees ideal adhesion and longevity. The process starts with thorough surface cleaning to remove dust, oil, and debris that might affect the epoxy's bond. Concrete Mike LLC utilizes professional-grade cleaners and mechanical techniques, like mechanical blasting or grinding, to create a pristine surface. Next, assess the concrete for defects or irregularities—these must be addressed to create a even foundation. Once the surface is smooth and dry, you'll apply a high-quality primer. This primer treatment is vital; it penetrates the concrete, closing gaps and facilitating strong adhesion for the epoxy layer. Hurrying through these steps can lead to adhesion failures or blistering, so careful execution at this stage guarantees a long-lasting finish.

Professional Epoxy Application Techniques

Once the surface has been properly prepared, the epoxy application starts with meticulous mixing of the two-part epoxy system according to recommended ratios. This process is essential; any variation can impact the final finish and durability. You'll pick your preferred shade at this stage, verifying the pigment is evenly dispersed throughout the mixture for even coverage. Utilizing rollers or squeegees, you'll apply the epoxy evenly over the floor, proceeding section by section to eliminate overlaps or inconsistencies. Pay close attention to corners and edges for a uniform application. Throughout the process, maintain epoxy safety by wearing gloves, respirators, and protective eyewear, and establish adequate ventilation. Attention to detail during these steps delivers a perfect, professional surface and creates long-lasting performance.

Curing and Finishing Methods

Although the application step sets the groundwork, it is the curing and finishing process that dictates the final durability and look of your epoxy flooring. During curing, you'll need to give the epoxy to cure undisturbed for the recommended period—typically 24 to 72 hours—guaranteeing ideal bond strength and durability. This stage is critical for securing your chosen color customization, as the pigments stabilize and achieve a uniform finish. After curing, a professional will assess the surface for any flaws, here then apply additional layers or texture as needed to enhance slip resistance. Proper finishing not only enhances the look but also improves practical performance, creating your floor safer and easier to maintain. You receive a floor that's both aesthetically pleasing and built to last.

Prime Areas for Epoxy Floor Solutions

When selecting the ideal setting for epoxy flooring, you'll discover its performance excels in both residential and commercial spaces that require durability, chemical resistance, and seamless aesthetics. In your home, epoxy is an ideal choice for garage floors, where vehicles and machinery, tools, and potential chemical spills need a robust, hardy surface. You'll find that epoxy withstands damage, stains, and wear, making maintenance and tidying effortless.

For industrial facilities, epoxy flooring delivers unmatched load-bearing capability and handles continuous forklift traffic, chemical spills, and intensive cleaning protocols. Its seamless finish minimizes dust accumulation and supports a enhanced safety working environment. Whether you're upgrading your garage or enhancing a large-scale facility, epoxy flooring delivers customized options—guaranteeing the surface matches both your operational needs and design expectations.

Essential Tips for Maintaining Long-Lasting Epoxy Floors

Given that epoxy floors are engineered for longevity, establishing a appropriate maintenance routine is essential to maximize their lifespan and maintain their appearance. Start by establishing consistent cleaning routines: remove debris daily and wash with a pH-neutral cleaner weekly. Avoid harsh chemicals, as they may harm the surface. Immediately clean spills, particularly oils and chemicals, to avoid staining or surface damage. Utilize soft-bristle brooms or microfiber mops to eliminate scratching. For enhanced protection, consider periodic application of specialized protective coatings designed for epoxy surfaces—these improve resistance against abrasion and chemical exposure. Place mats at entryways to reduce dirt and grit, and attach furniture pads to avoid gouging. By adhering to these proactive steps, you'll guarantee your epoxy floor maintains its strength, gloss, and seamless look for years.

Reasons to Select Concrete Mike LLC for Your Flooring Needs

If you're looking for a flooring expert who merges professional knowledge with a commitment to enduring results, Concrete Mike LLC stands out as the clear choice for epoxy flooring in Satellite Beach. You receive a team that emphasizes exactness and resilience, making sure your floors handle intensive wear and environmental conditions. Concrete Mike LLC employs state-of-the-art, low-VOC materials, decreasing environmental impact without sacrificing performance. Their meticulous approach guarantees every layer is appropriately prepared and applied, minimizing maintenance needs over time.

When you examine a price analysis, you'll discover that Concrete Mike LLC delivers remarkable value. Their installations are designed to outlast traditional choices, lowering your expenses on maintenance and upkeep. By prioritizing technical excellence and environmentally conscious approaches, they deliver flooring solutions built for both durability and performance.

Success Stories and Featured Projects

Although each project presents its own challenges, Concrete Mike LLC consistently delivers outstanding results that surpass client expectations. You'll appreciate how our approach focuses on technical precision—if you require a stunning showroom floor or a long-lasting garage surface, we tailor solutions to your unique needs. Clients value our transparent cost estimates, guaranteeing there are no surprises during installation. We walk you through a selection of color options, enabling you choose the ideal shade and finish to elevate your space.

For example, a recent residential installation in Satellite Beach featured custom blue epoxy with anti-slip additives, offering both beauty and security. A different highlight involved a commercial facility where we aligned corporate branding with exact color options, delivering both resilience and aesthetic consistency. Your happiness motivates our detailed process.

Questions & Answers

What's the Average Cost per Square Foot for Epoxy Flooring in Satellite Beach?

As you explore epoxy flooring, expect pricing in Satellite Beach to vary between $4 to $10 per square foot. The overall expense varies based on several components, including your area's dimensions, the type of epoxy, substrate preparation, and any custom finishes. It's important to get a comprehensive estimate so you can review all cost factors and verify your investment fulfills both your performance and aesthetic requirements.

Is Epoxy Flooring Safe for Homes With Pets and Children?

Feel secure about pet safety and child protection with professionally installed epoxy flooring. Once cured, epoxy's non-porous surface prevents scratches, staining, and water damage, making it easy to clean up after spills or accidents. While epoxy installation produces vapors and present epoxy toxicity risks, qualified technicians maintain proper curing and sufficient airflow. Make sure to exclude pets and children during installation, but post-curing, you'll benefit from a secure, long-lasting floor system for your home.

What's the Required Curing Time for Epoxy Flooring?

Imagine epoxy flooring as a protective shield hardening gradually—patience is key to durability. You must allow a 12 to 24 hour period for the initial drying phase, when it becomes safe for gentle foot traffic. Nevertheless, the complete curing process needs 5-7 days until you're able to move in heavy furniture or vehicles. By adhering to this timeline, you'll secure your floor's longevity and durability, stopping premature damage and creating a perfect, long-lasting finish.

Can Concrete Cracks Be Addressed Prior to Epoxy Treatment

Indeed, you're able to address existing damaged concrete before applying epoxy. For effective crack repair and concrete restoration, it's essential to thoroughly clean the cracks, remove any loose debris, and utilize an appropriate filler or epoxy-based crack repair compound. After the repairs set, level the surface through grinding to ensure a flawless finish. This comprehensive prep work ensures optimal epoxy bonding and long-lasting results, preventing issues from resurfacing beneath the new flooring.

How Can You Pay at Our Company Take for Flooring Services?

Picture the joy of transforming your floors, weighed against the concern of planning to pay. Rest assured—there are flexible payment options available. You can select from different payment options, ensuring flexibility. If you want to spread payments, financing plans are extended to help you finance easily. Therefore, you can concentrate on the improvements, certain you've got flexible, dependable solutions for your flooring upgrade.

Final Overview

If you need resilient, stunning, and reliable flooring, epoxy provides a lasting solution for Satellite Beach spaces. With seamless surfaces, simple maintenance, and stunning style, you'll see and feel the difference every day. Trust Concrete Mike LLC's technical talent to transform worn concrete into mesmerizing, customized creations. Let's safeguard your surfaces with advanced systems that stand strong against messes, discoloration, and scratches. Select Concrete Mike LLC—where superiority, craftsmanship, and customer care come together for perfect, functional floors.

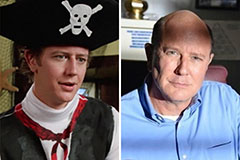

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!